| Application | Installation of casings to granite bedrock through granite blast-rock boulders in reclamation fill |

|---|---|

| Location | Hong Kong |

| Hammer | Numa 240 Hammer |

| Bit | Super Jaws® T710 Overburden Bit |

| Hole Size | Reamed diameter 30.88 inch (784 mm) |

| Depth or Length | Up to 187 feet (57 m), 18° & 20° below horizontal |

| Formation | Granite blast-rock boulders and granite bedrock |

| Rig Type | Elettari rated 400T Horizontal Boring Machine |

Description

When China Light & Power awarded Skanska International Civil Engineering AB the world’s largest directional drilling (HDD) contract there were only a few viable alternatives available to them in order to complete the demanding project. After evaluating the market, Skanska awarded the HDD contract to A.J. Lucas (Hong Kong) Ltd., who had extensive previous experience completing 2 x 32-1/4″ (820mm) 4,495 foot (1370 m) bores to carry water mains to Ma Wan Island.

When China Light & Power awarded Skanska International Civil Engineering AB the world’s largest directional drilling (HDD) contract there were only a few viable alternatives available to them in order to complete the demanding project. After evaluating the market, Skanska awarded the HDD contract to A.J. Lucas (Hong Kong) Ltd., who had extensive previous experience completing 2 x 32-1/4″ (820mm) 4,495 foot (1370 m) bores to carry water mains to Ma Wan Island.

The project required the drilling and installation of six (6) high-voltage cable ducts to provide power to new development on Ma Wan Island, between the mainland and Lantau Island. Two cable ducts were launched from Sham Tseng, New Territories, each 4,330 feet (1,320 m) long, and 23 inches (584 mm) finished diameter. Four (4) cable ducts were launched from Lantau Island, each 2,789 feet (850 m) long. The inner steel lining pulled through the bores were 16″ (406 mm) O.D.

The launch direction and entry angle of two ducts at the Lantau Island site placed them in the path of the blast-rock granite boulder reclamation fill which created major problems with loss of mud circulation and failure of tooling in one of the bores.

The launch direction and entry angle of two ducts at the Lantau Island site placed them in the path of the blast-rock granite boulder reclamation fill which created major problems with loss of mud circulation and failure of tooling in one of the bores.

After investigating available methods of penetrating the seawall, A.J. Lucas concluded that a proven under-reaming system would be the best method of establishing the portal entries. The contractor worked with Numa and Numa’s Hong Kong distributor Fedco Ltd., to mobilize the necessary tooling in a minimum amount of time in order to begin drilling.

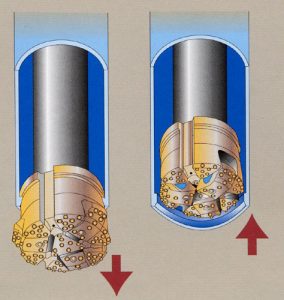

Numa 240 DTH hammers, hdd hammers, casting hammers, and Super Jaws® T710 underreaming system bits were selected for the drilling and casing installation due to their reputation as the most reliable products available on the market. The Super Jaws® Bit, manufactured by Numa under license from Tone Corporation, is a special under reaming wing bit design made for simultaneously setting casing while drilling. It is engineered with wings that extend out further than the casing while in the drill position to allow casing to be pulled down the hole while drilling. The under reaming concept allows the full face of the bit to be in constant contact with the rock formation to easily break up boulders and any other rock formations encountered. This lowers the torque and reduces the possible damage to the rotation head motor as well as lowering the possibility of a shank failure. The under reaming bit also does not require the use of costly ring bits or casing shoes that remain down the hole when drilling is complete. Once drilling is complete, the wings retract back inside the casing and the entire bit is brought to the surface while the casing is left securely down the hole.

Numa 240 DTH hammers, hdd hammers, casting hammers, and Super Jaws® T710 underreaming system bits were selected for the drilling and casing installation due to their reputation as the most reliable products available on the market. The Super Jaws® Bit, manufactured by Numa under license from Tone Corporation, is a special under reaming wing bit design made for simultaneously setting casing while drilling. It is engineered with wings that extend out further than the casing while in the drill position to allow casing to be pulled down the hole while drilling. The under reaming concept allows the full face of the bit to be in constant contact with the rock formation to easily break up boulders and any other rock formations encountered. This lowers the torque and reduces the possible damage to the rotation head motor as well as lowering the possibility of a shank failure. The under reaming bit also does not require the use of costly ring bits or casing shoes that remain down the hole when drilling is complete. Once drilling is complete, the wings retract back inside the casing and the entire bit is brought to the surface while the casing is left securely down the hole.

Drilling on the project was conducted from an Elettari rated 400T rig with 882,000 lb thrust, 157.8 kNm (116,353 ft lb) of torque and three (3) air compressors with a combined capacity of 2740 CFM (1293 l/sec). To install 30 inch (762 mm) casing with 1/2 inch (12.7 mm) wall, 30.88 inch (784 mm) diameter holes were drilled by the Numa 240 and Super Jaws® Bit. Three casings in all were installed. The first down to the failed tooling was 98 feet (30 m) long, at 18° below. The second was 187 feet (57 m) that established a new bore portal entry, also at 18° below. The third casing was 177 feet (54 m), drilled at 20° directly under the casing which had intersected the failed tooling, to reestablish the portal entry for that bore. The tooling was recovered by divers after completion of all drilling.

Drilling on the project was conducted from an Elettari rated 400T rig with 882,000 lb thrust, 157.8 kNm (116,353 ft lb) of torque and three (3) air compressors with a combined capacity of 2740 CFM (1293 l/sec). To install 30 inch (762 mm) casing with 1/2 inch (12.7 mm) wall, 30.88 inch (784 mm) diameter holes were drilled by the Numa 240 and Super Jaws® Bit. Three casings in all were installed. The first down to the failed tooling was 98 feet (30 m) long, at 18° below. The second was 187 feet (57 m) that established a new bore portal entry, also at 18° below. The third casing was 177 feet (54 m), drilled at 20° directly under the casing which had intersected the failed tooling, to reestablish the portal entry for that bore. The tooling was recovered by divers after completion of all drilling.

The 30 inch (762 mm) casings used during the project were in 29.5 foot (9 m) lengths. During the installation of the first casing down to the tooling, the contractor proceeded carefully to become familiar with the drilling method and until contact with the tooling was made. The second bore, totaling 187 foot (57 m), was completed in just two days including the welding of casing. The second and third casings were drilled through the granite boulders and keyed into granite bedrock more quickly each time. In all cases, the Numa 240 and Super Jaws® bits worked flawlessly to complete the holes.

The 30 inch (762 mm) casings used during the project were in 29.5 foot (9 m) lengths. During the installation of the first casing down to the tooling, the contractor proceeded carefully to become familiar with the drilling method and until contact with the tooling was made. The second bore, totaling 187 foot (57 m), was completed in just two days including the welding of casing. The second and third casings were drilled through the granite boulders and keyed into granite bedrock more quickly each time. In all cases, the Numa 240 and Super Jaws® bits worked flawlessly to complete the holes.

This project was one that demanded reliable tools that could perform in difficult conditions. Numa’s 240 hammer and Super Jaws® Bit did not disappoint as the project was successfully completed beyond everyone’s expectations. A.J. Lucas reported they were “extremely impressed with the performance” of the tools.

Get to the bottom of it with Numa.